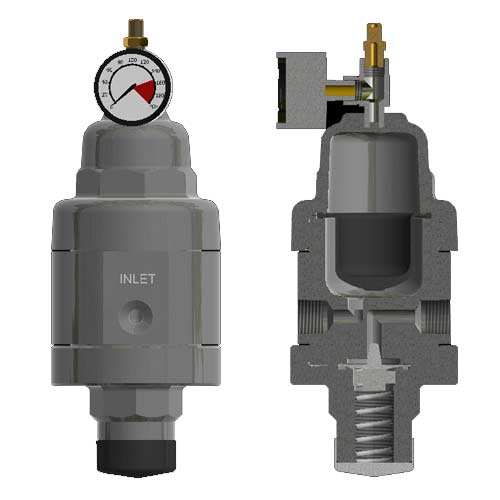

SENTINEL Diaphragm Back Pressure Valves

Prevent siphoning and stabilize dosage rates with SENTINEL Diaphragm Back Pressure Valves

Diaphragm back pressure valves are designed to enhance the performance of pumping systems by applying a continuous back pressure to the system pump, while also acting as an anti-syphon valve. Robust construction ensures reliability in the rigorous service of municipal and industrial applications.

- Reliability and low cost

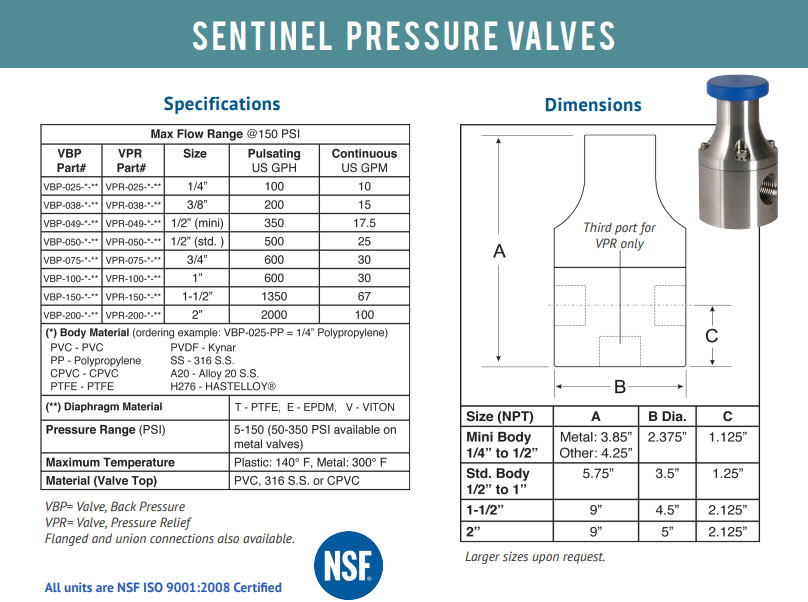

- Adjustable 5-150 psi for standard, 5-50 psi low pressure, or 50-350 psi high pressure

- Anti-siphon function

- Robust machined construction

- Vulcanized PTFE/EPDM diaphragm

- Full range of chemically resistant wetted materials

- Sizes from ¼” to 4” depending on model

Diaphragm back pressure valves apply positive discharge pressure to a metering pump system to prevent siphoning and eliminate varying dosage rates caused by fluctuating downstream pressure. The diaphragm is held against the valve seat by an internal spring. When the preset pressure is exceeded, the diaphragm is forced up and system fluid flows through the valve to the injection point. The valves are preset for 50 psi, however they are field adjustable from 5 to 150 psi, (optional up to 350 psi for high pressure) via the adjustment screw. Installation should be as close to the injection point as possible to prevent system line drainage, and it is most important that all pumping system equipment such as pulsation dampeners and pressure gauges are between the pump and back pressure valve

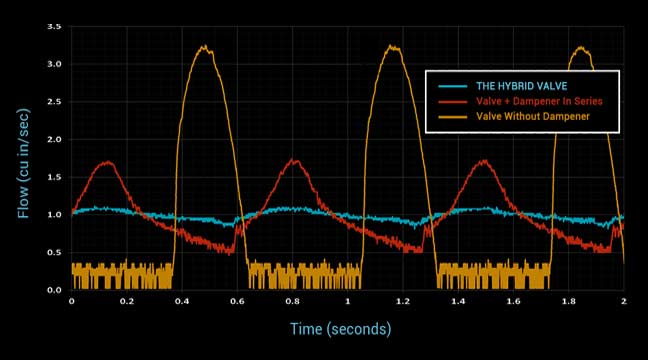

remove hydraulic shock and vibration, enhancing all-around performance and reliability of fluid flow applications.

remove hydraulic shock and vibration, enhancing all-around performance and reliability of fluid flow applications.

Fully Automatic Air Control

Fully Automatic Air Control