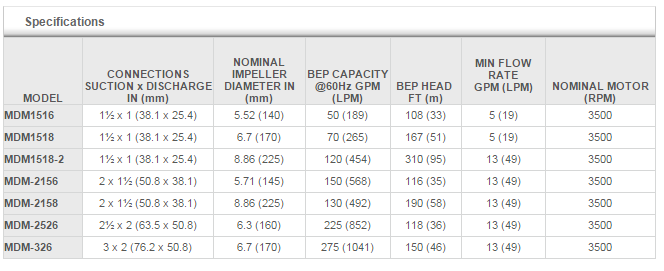

Motor 2 to 25 HP Max. 1325 L / min

MDM pumps are magnetic centrifugal pumps developed for a wide range of applications. The turbine in the volute (front body) is rotated by a magnetic force to transfer the liquid from the suction to the discharge of the pump. MDM pumps have excellent corrosion resistance, a long service life, high

safety and are used for pumping chemicals in different applications. Many chemicals can be transferred by these pumps.

Maximum Capacity: Up to 1325 L / min

Innovative, the Magnetic Pump series MDM brings notable progress in terms of comfort, safety of use and respect for the environment. It contributes to substantial savings due to its robustness and reliability by minimizing downtime and requiring little maintenance.

MDM Magnetic Pump – An Exclusive Mechanism for Preventing Dry Running

This magnetic pump is equipped with a device to avoid the effects of dry operation. The exceptional power of the magnets used (in rare earths) avoids contact of the magnetic capsule with the backstop and eliminates the risk of friction and heating due to melting of synthetic materials. This device achieves better resistance against dry running compared to traditional magnetic pumps.

Note: Only CF type magnetic pumps (with high density carbon bearings) can withstand dry operation. The latter is to be avoided in the case of parts of type KK (silicon carbide).

Magnetic pump MDM – Components of extreme reliability

The front body ETFE is reinforced with carbon fibers for improved both strength and corrosion while the outer peripheral surfaces are reinforced with ductile iron to a more Long life.

For the PFA MDM series, the ductile iron front body consists of a single piece coated with virgin fluorinated resin.

A new concept was adopted for the construction of the turbine. It is a “peg-fit” system that optimizes the axial maintenance of the turbine. Closed turbines are designed to ensure high efficiency. In addition, the rear body made of carbon-filled fluorine-containing resin is resistant to a pressure of 16 bar. It eliminates eddy currents and the production of sparks. Moreover, when dismantling for maintenance, any leakage of product proves impossible, the front and rear bodies being held in place by a flange. This advantage also contributes to respect for the environment.

Magnetic Drive Pump MDM – release rear System (Pull-Back)

A special removal system is intended to facilitate maintenance of the magnetic pump. The interior of the unit can be easily inspected and parts can be replaced without disassembling the piping. This device is designed to prevent any leakage of liquid during the extraction of the motor assembly, spacer and magnetic drive